When we return a customer’s knives, we're often asked something to the effect of,

“Wow! How do I keep them like this?”

Here's all you really need to know, condensed into a simple set of rules.

If you want more information, just click the rule.

The majority of modern kitchen knives are made from some sort of stainless steel. We’re ignoring carbon-steel (the other kind) for the purposes of this post. If you own any of those, you probably know the deal. Ceramic knives will be covered in a future post, but all the advice here applies to those as well (albeit for slightly different reasons).

All stainless steels are corrosion-resistant to some degree – it’s in the name. However, that doesn’t mean you should chuck your knives in the dishwasher along with your stainless pots and flatware! Quality knives are made of knife steels: a set of alloys specifically engineered for durability and edge-retention.

However, this comes at some cost to corrosion resistance (you can’t have it all).

A stainless knife laying on a wet cutting board will rarely suffer harm. However, the hot water and detergent in a dishwasher create a harsh chemical

environment that attacks steel – amplified by prolonged exposure. Even if there’s no visible pitting or rust, microscopic corrosion on the

cutting edge contributes to premature dulling. What’s more, banging around with utensils and plates is a sure way to mechanically dull or

damage an edge in short order.

Just take a minute to hand-wash and dry your knives. It will keep them in good shape for years to come.

Believe it or not, we encourage people to learn how to sharpen on their own. We’re happy to offer guidance – just ask!

The thing is, nobody has yet invented a truly “no-skill” sharpening gadget (let alone a cheap one) that isn’t hot garbage.

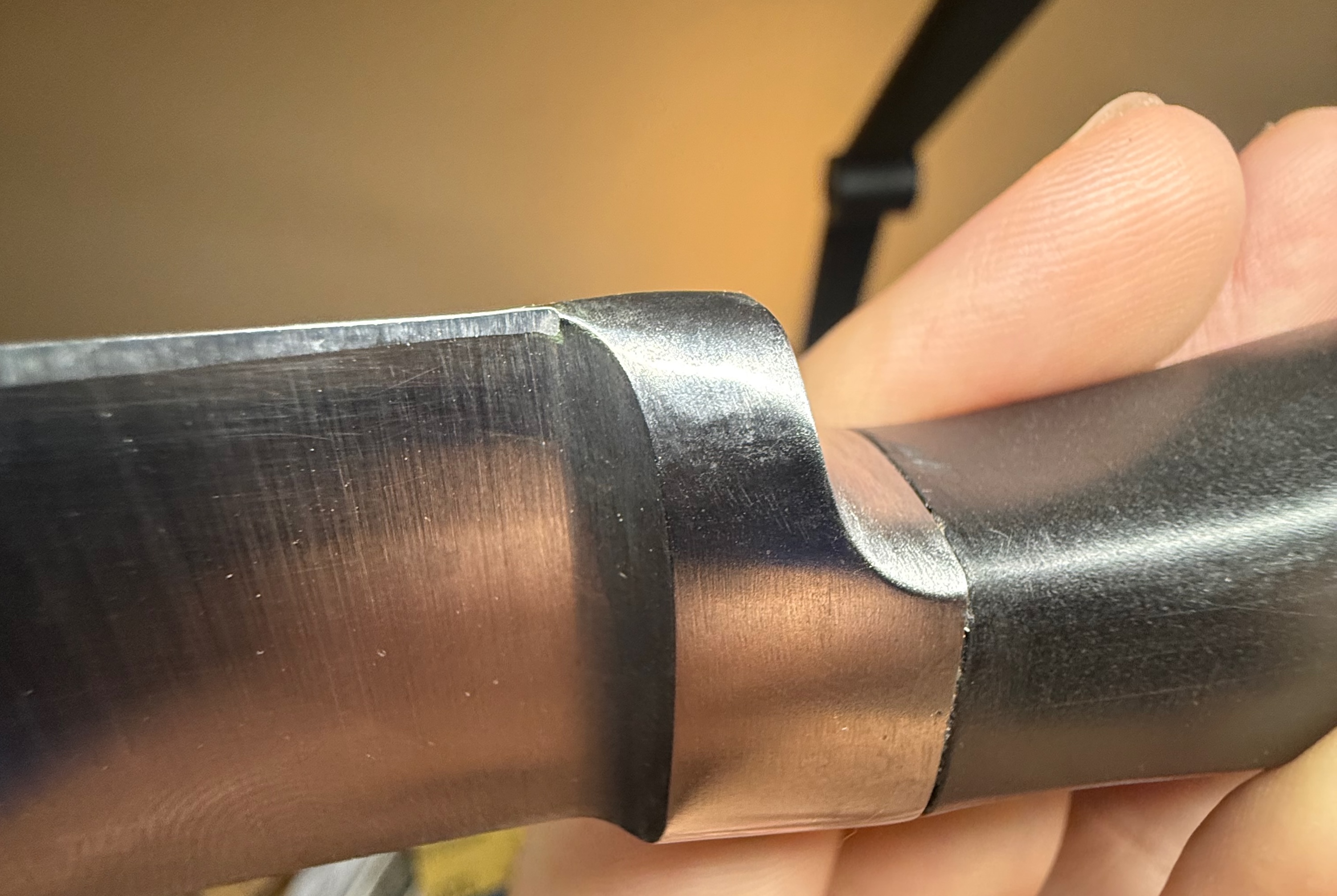

We can instantly spot a knife that’s been subjected to a pull-through, via the telltale scratches and chewed-up, irregular edges.

They're all built much the same. There's a “coarse” side featuring carbide teeth that brutally rip away steel in order to create

something approximating a cutting edge. That awful sound you hear? It’s your knife screaming in pain.

Meanwhile, the ceramic rods on the “fine” side are far too fine to appreciably improve the carnage left by the carbide.

These things just plain don’t work very well, unless your goal is to accelerate

the demise of a knife.

If you want a sharpener that is no more difficult to use than a pull-thorugh, but delivers very good results, the Tormek T1 is for you.

Another excellent machine at a slightly lower price is the Ken Onion Elite from WorkSharp.

A cutting board should be soft enough to allow a sharp knife to dig in, just a bit, and glide along its edge (think of an ice skate). This makes your cuts more controlled (e.g. safer),

and avoids premature dulling. Here are the most common materials for cutting boards, ranked from best to worst in terms of knife-friendliness:

- End-grain wood: top-shelf performance and price, some upkeep required. You can spot these by the distinctive checkerboard pattern.

- Rubber: comparable performance to end-grain, but very low-maintenance. Still a bit spendy. Popular among pro chefs.

- Edge-grain (“regular”) wood: the traditional choice, and still a good one. Strikes a nice balance between performance, maintenance, and cost. If you want “plenty good enough” without spending a lot, you can stop reading here. It only goes downhill.

- HDPE (white plastic): standard in commercial kitchens, mainly because it can survive a commercial dishwasher. For home cooks, the deep, permanent scratches it accumulates can actually harbor bacteria. It's also a bit harder on your knives than any of the above options. Not great, not awful.

- Bamboo: very affordable, often marketed as eco-friendly. Unfortunately, it’s a very tough and fibrous material that will wear down your edges rather quickly. Even for the casual home cook, it’s worth upgrading to wood.

- Glass / granite / marble: Sigh. While we love repeat business, for us to endorse these would be like a dentist telling her patients to quit flossing and drink more soda. Please don’t use these as cutting boards.

People seem to like them because they don’t scratch. That's because they're harder than most steel – so they chew up your knives instead. They're also a little dangerous (see top of this section), loud and unpleasant to use.

If you have one, keep it for serving and keep your knives well clear of it.

Storing knives loose in the utensil drawer is one of the quickest ways to dull or chip them.

Every time they bump against each other or other utensils, tiny impacts deform the edge. It’s also a good way to cut yourself when

rummaging for something else (ask us how we know).

Our favorite way to store knives is out in the open, on a magnetic wall strip or a magnetic counter block. These save space and allow any residual moisture to easily dry.

Traditional counter blocks are fine, too. Just be sure your knives are thoroughly cleaned and dried before they're put away, lest things get funky in there. Bonus points if you store

them edge-UP, dragging the spine against the block instead of the edge – they'll stay sharp longer.

If you need or prefer to use a drawer (perhaps a locking one for child safety), that's no problem. There are plenty of options for in-drawer organizers

that will help protect your knives and your fingers. We like the designs that use vertical "fins" made of cork. Just as with blocks, make sure everything is clean and dry before storage.

If some of this information is new to you, and you're worried that your knives might be worse for it – don't stress! So long as it's still in one piece (or even if it's missing a tip!), you haven't done anything that we can't fix. We promise not to lecture you about it, too.

We hope this has been helpful or at least interesting. As always, if you have any questions, feel free to reach out!

On Value Propositions

Posted 10/16/2025 • 3–4 min read

When choosing a provider for most any trade or service, you'd be wise to remember this old maxim: "You want cheap, fast, and good. Pick two". Let's take a look at the major categories that most commercial sharpeners fall into, and see how they illustrate this principle.

A few national retailers offer in-store sharpening with very attractive pricing. These are usually a "loss-leader" proposition;

the intent is simply to get you in the door, in the hope that you buy something. These services all use some sort of automated machine

in order to take knowledge and skill out of the equation – and it shows. Will your dull knives come back sharper? Sure! Will they be factory-sharp or better, and keep that edge for a long time? Not likely.

Will they get scratched or damaged? Frequently, yes. Please do not risk your cherished or expensive knives at these places – and hobble their performance –

just to save a few dollars. They are cheap and fast, but they are not good.

Many independent sharpeners operate at farmers markets, or outside grocery stores. This "while you shop" convenience is great for customers, but

it also means they must be fast – and that will dictate their choice of equipment and methods to a great extent.

That doesn't mean they're bad! Indeed, some do beautiful work – but rarely at bargain-basement prices.

In other words: they're all fast. Some are cheap, others are good.

Where does Carlsbad Sharpening fit in? We insist on delivering the absolute highest-quality work we're capable of, and on seeking constant improvement.

This is non-negotiable for us. We aim to be fast enough and to keep our prices competitive, within that constraint. While we'll

never compete on sheer speed, our FREE local pickup and delivery (5+ items) matches or exceeds anyone in terms of overall convenience.

If that sounds like a good value to you, give us a try! We'll be glad to show you what sets us apart.

Click to expand